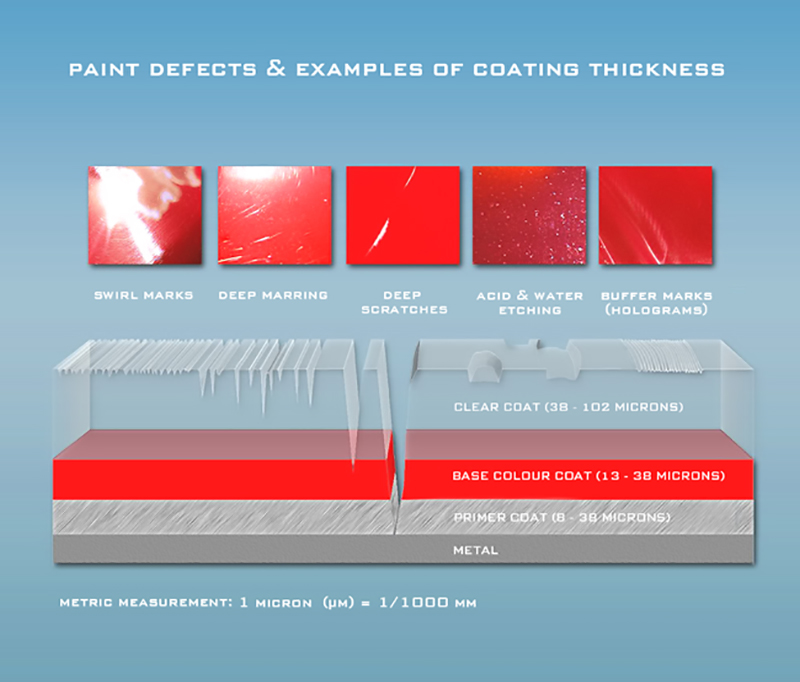

Thinning paint can indicate deterioration. Paint thickness gauges can also be used for system and machine maintenance.In industries, manufacturers use these gauges to make sure their products achieve required standards.Inconsistency in paint thickness is an indicator of a repair having been done because of corrosion, an accident or some other issue. You can use a paint thickness gauge when you are inspecting a used car to tell which panels have undergone repairs.If the paint is thin, polishing off too much can expose the lower paint layers. Car detailers use a paint thickness gauge to determine how much paint they have to work with.Here are some of their most common applications as well as their biggest benefits. Uses And Benefits Of A Paint Thickness GaugeĪs I mentioned, paint thickness gauges are used across a wide range of industries. They use the reflected pulse to determine paint thickness. Ultrasonic paint thickness gauges work by sending a pulse through the paint. These are used on non-metal surfaces such as plastic, wood and fiberglass. There are gauges that don’t rely on magnetism at all. Many paint thickness gauges today have a 2-in-1 design: they can measure via magnetic induction or eddy currents, giving you more versatility. The probe measures the nature and strength of the magnetic fields to determine paint thickness. These eddy currents have their own magnetic fields. By measuring changes in the magnetic field, the gauge can determine paint thickness.Įddy currents are used to measure the thickness of non-conductive coatings on non-magnetic metal surfaces such as aluminium or non-ferrous stainless steel.Ī coil carrying a high frequency alternating current causes eddy currents in the substrate. More advanced paint thickness gauges use either electromagnetic induction or eddy currents.Įlectromagnetic induction is used to measure thickness of non-magnetic coatings on magnetic surfaces such as steel.Ī coil system generates an electromagnetic field that is affected by the magnetic substrate. The gauge gives a readout in μm (micrometre/micron). This correlates to paint thickness – the more the required force the thicker the paint. A sensor then measures how much force it has taken to pull off the magnet. Increasing tension is applied to a spring connected to the magnet. Once you place the gauge on the surface, a magnet attaches to the surface.įor this type of gauge to work, the surface underneath has to be a ferrous (magnetic) material like steel. Some paint thickness gauges use a permanent magnet to measure paint thickness. Blue Technology P 11-S-AL Paint Coating Thickness Meter Prodig-Tech GL8s Digital Car Paint Layer Thickness Meter Amgaze Digital Ultrasonic Thickness Meter Tester

Digital CEM DT-156 Paint Coating Thickness Meter

Paint depth gauge detailing full#

I wouldn’t want to do a full two step on a new car unless they are planning on a PPF or they know proper care of their paint to avoid it being a reoccurring event.

Paint depth gauge detailing driver#

So a 2008 daily driver you can do a full two step on and look fantastic. Most cars it isn’t a problem because most people don’t have their car detailed often. I think tell the customer and explain that depending what they are looking to get out of this paint correction, I shouldn’t get everything to be new again. Subtract the baseline number and that’s the APPROXIMATE clear coat depth. Then go around the whole car taking measurements and write down each body panels average. Usually what I’ll do is open the hood, trunk or gas door and look for an area that was obviously not clear coated and only painted and I’ll write that down as a baseline. The numbers don’t mean crap if you don’t know how accurate they are. I think that’s a key part to look for in one. It has a piece of aluminum and steel and about 7 varying thickness sheets to compare to for accuracy and to calibrate. I’ve got one off amazon, the ERAY paint thickness gauge.

0 kommentar(er)

0 kommentar(er)